Mopar 440 Intake Manifold Torque Sequence and Specs

There are many questions about the torque specs for a Mopar 440 intake manifold. There is different specs depending on the year.

The Mopar 440, 1969-1978, factory cast iron intake manifold bolts are torqued to 40 foot-pounds. The Chrysler service manual states for the years 1966-1968, the intake manifold bolts are torqued to 50 foot-pounds. The torque sequence starts with the inside bolts towards the outside bolts.

This article will also explain the torque sequence for the bolts. In addition, torque specs for aluminum intake manifolds because those differ from the factory.

Mopar 440 Intake Manifold Torque Specs

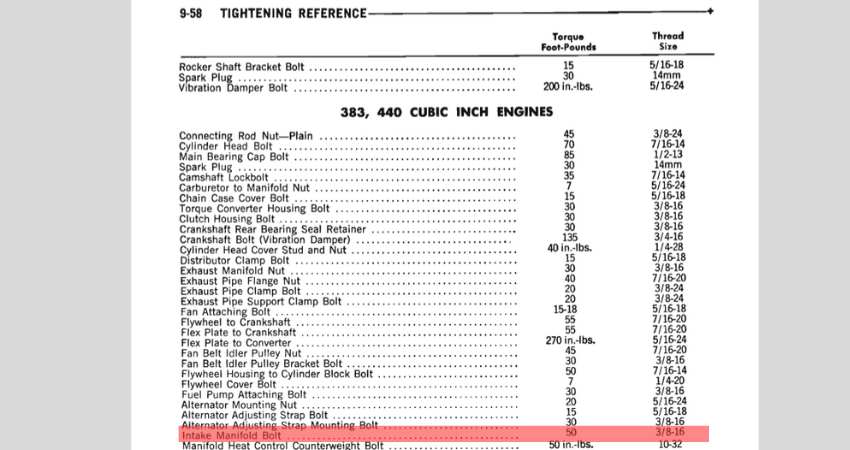

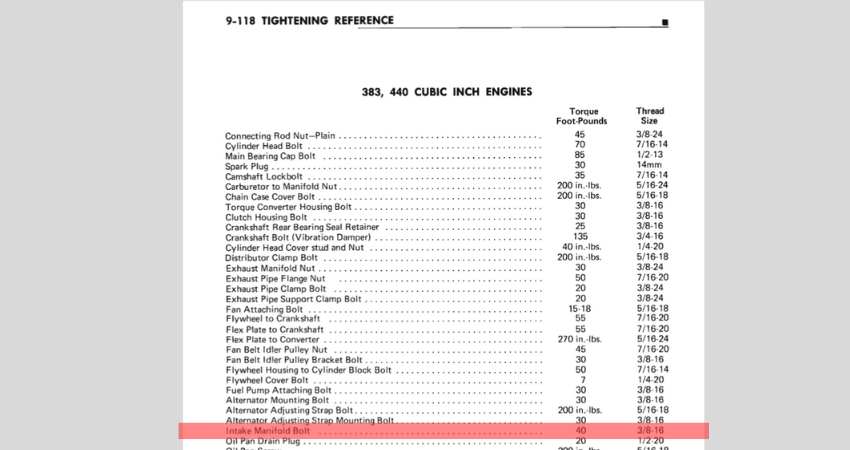

As per the Chrysler engine service manuals, the following is the torque specs for a Mopar 440 1966-1968:

- 50 foot-pounds

As per the Chrysler service manuals, the following is the torque specs for a Mopar 440 1969-1978:

- 40 foot-pounds

The Chrysler service manual doesn’t go into much detail about the intake manifold bolts for the 440 engine. As a matter of fact, they create much confusion.

In the Chrysler service manual tightening reference section for 1969-1978, it states the intake manifold bolts should be torqued to 40 foot-pounds.

In the Chrysler service manual tightening reference section for 1966-1968, it states the intake manifold bolts should be torqued to 50 foot-pounds.

In the 1969 service manual, in the cylinder head assembly instructions, they state a higher torque setting (50 foot-pounds) for the intake manifold than what they state in the tightening reference (40 foot-pounds) of the same manual.

Most people follow and recommend the tightening reference section in the 1969-1978 Chrysler manuals, which states 40 foot-pounds.

In the engine section they don’t explain if the 40 foot-pounds should be accomplished in multiple steps or the proper sequence.

Most engine builders recommend two steps, the 1st, approximately 25 foot-pounds and the 2nd at 40 foot-pounds.

I typically use two steps, 25 and then 40 ft. lbs. I also recheck the torque after the final step to make sure each bolt remained at its proper tightness and to identify if a bolt was missed.

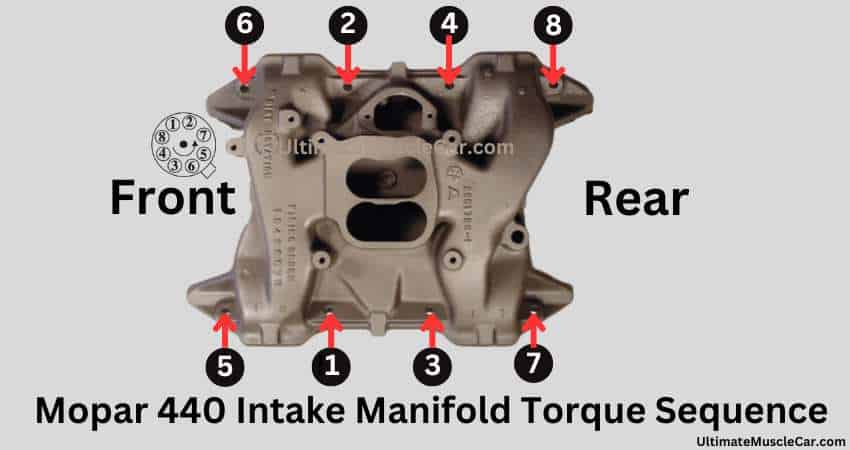

440 Intake Manifold Torque Sequence

The Chrysler service manuals do not recommend an intake manifold torque sequence for the big blocks or the 440 engines. They do recommend one for the small blocks.

In other Mopar publications for their aftermarket 440 aluminum manifolds, they do recommend two steps and a sequence. That sequence follows the same sequence as specified for the Mopar small block in the Chrysler service manual.

Most people follow and recommend the same sequence Mopar recommends for their 440 aftermarket manifold and the small block sequence stated in the factory service manual.

Of course the Mopar small block has more intake manifold bolts (12) than the big block’s eight bolts. Therefore, the sequence would be followed only for the 1st eight bolts.

The 440 intake manifold sequence, shown above, starts with the inside bolts and continues towards the outer bolts until all eight bolts are completed.

440 Aluminum Intake Manifold Torque Specs

The aluminum intake manifolds follow the same torque sequence as a cast iron manifold. Although the torque foot-pounds are less for aluminum intakes.

Edelbrock and Mopar Performance recommend 25 foot-pounds in two steps for their Performer series 440 manifolds.

Always Check with the manufacturer of the intake manifold you are installing for their torque recommendation.

Always use thick, flat washers. Using just the bolts will score and damage the aluminum.

Except for the 440 Six Pack in 1969, aluminum manifolds weren’t used for the 440 from the factory.

The Torque Wrench Won’t Fit

Depending on your intake manifold, the torque wrench may not fit on one or more of the bolts.

The answer is a torque wrench adaptor, aka crow’s foot. They are about 2″ long. One end attaches to the torque wrench and the other end to the bolt.

The problem using a crow’s foot is they change the leverage of the wrench increasing the torque.

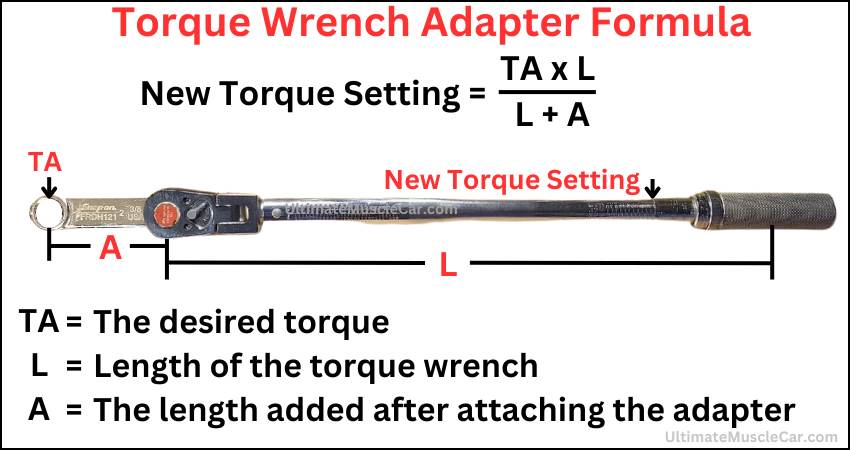

The following formula must be used to adjust the torque used.

Torque Wrench Adaptor Formula

The following is the torque wrench adapter formula:

TA x L / L + A = New torque setting

- TA= The desired torque

- L= The length of the torque wrench (From the center of the handle to the center of the square drive).

- A= The length added after attaching the adaptor. (From the center of the square drive to the center wrench drive/opening).

- New torque setting (This will be lower than the desired torque).

Let’s run this formula through an example. In this example:

- I wish to torque the 440 intake manifold bolts to 40 ft. lbs (TA).

- I’m using a Snap-on torque wrench measuring 20 inches from the center of the handle to the center of the square drive (L).

- The adapter is 2″ long (A).

Let’s apply the formula:

- 40 (TA) x 20 (L)=800

- 800/20 (L) + 2 (A)

- 800/22=36.3 (New torque setting)

Therefore, I would have to set the torque wrench at 36.3 to achieve my desired torque of 40 foot-pounds.

Don’t want to purchase an adaptor?

- Others will get a feel for the tightness of the torqued bolts and apply that feel to the other bolts which the wrench won’t fit on.

- Borrow an adaptor.

- Many people don’t torque their intake manifold bolts at all.

- I recommend torquing the bolts. A proper seal is essential on an intake.

Check out other intake manifold torque specs here:

Aftermarket Studs or Bolts

Different bolts and the use of studs may change the torque specs used although the sequence would remain the same. Always check with the manufacturer of the bolts or studs for their recommendations.

If you have any questions about the intake manifold torque specs for a Mopar 440, send us an email found specifically on our contact page.

For the past 40 years, I’ve been studying and researching Mopar engines including intake manifolds. I torqued my first 440 intake manifold 38 years ago while building my first 440 Mopar engine.

More Mopar 440 Engine Articles

Mopar 440 Head Bolt Torque Sequence and Torque Specs